ITIUK

Pressure Gauge

Selection Information

Pressure Gauge Selection Information

Gauge Design

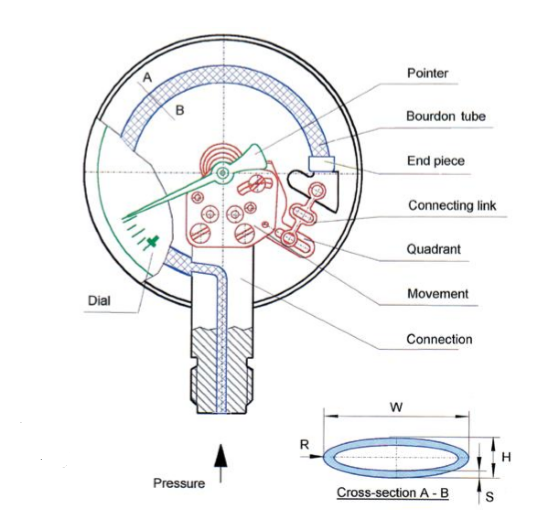

Pressure gauges are defined as “an instrument for measuring the pressure of gases or liquids, consisting of a semicircular or coiled, flexible metal tube attached to a gauge that records the degree to which the tube is straightened by the pressure of the gas or liquid inside” 1

Invented and patented by Eugene Bourdon in 1847, the bourdon tube pressure gauge is the second most mass produced instrument in the world, second only to the wristwatch.

The diagram below shows the parts and components that make up a pressure gauge:

Gauge Type

Pressure gauges are often categorised in different ways, however, most commonly they are split into two categories:

Process Gauges

High Quality Gauges.

These are often used in Dairies, Breweries, as well as the Pharmaceutical and Chemical Industry, and similar.

Utility Gauges

Low Cost Gauges.

These are commonly used for every day use on Pumps, Compressors, Pneumatic Systems and similar.

Gauge Case

Gauge cases are available in various materials:

Stainless Steel 304

Stainless Steel 316L

Carbon Steel (Painted Black)

Plastic (ABS) and Thermoplastics

Gauge / Dial Size

ITIUK supply gauges in the following sizes:

40mm (1½ inch)

50mm (2 inch)

63mm (2½ inch)

100mm (4 inch)

150mm / 160mm (6 inch)

250mm (10 inch)

It is important to select a dial size that is easily read at a normal reading distance, once the gauge is installed.

Gauge Mounting

Gauges can be mounted in different ways, either directly or with the use of a mounting flange or clamp fixing.

Most pressure gauges can be supplied with the following connections:

- Bottom Entry

- Centre Back Entry

- Lower Back Entry

Pressure gauges should be mounted in the upright position wherever possible.

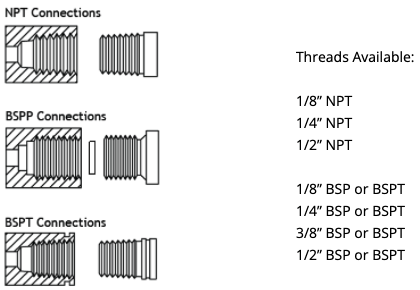

Gauge Threads

Standard pressure gauges can be supplied with NPT, BSP or BSPT threaded connections.

Threads available in Stainless Steel, Brass & Monel (Wetted Parts)

Gauge Material

It is critical that the materials of the gauge’s pressure system are compatible with the media that it’s measuring.

Typical tube and construction includes:

- 316L SS Bourdon Tube with SS 316L Socket (for up to 200°C / 392°F)

- Phosphor Bronze Bourdon Tube with Brass Socket (for up to 80°C / 176°F)

For applications where standard gauge materials or fluid characteristics are not compatible with the media, a diaphragm seal may be needed to protect the pressure instrument.

Gauge Ranges

The maximum operating pressure should not exceed 75% of the full-scale range.

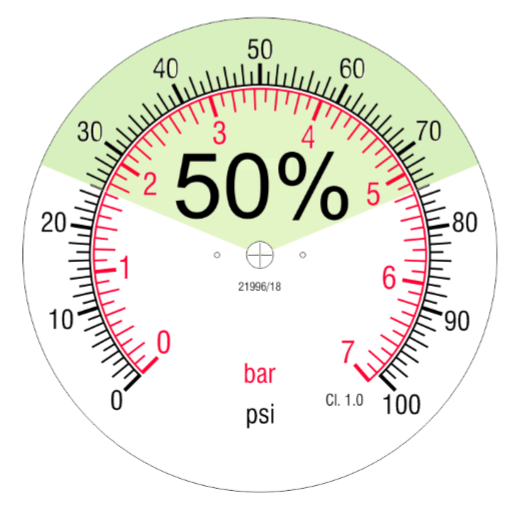

The normal operating range should be in the middle half of the range whenever possible. For example, if a customer’s process is at 50 psi, a Pressure Gauge with a range of 0 to 100 psi, should be selected.

Typical pressure ranges of gauges include:

0 to 15 psi 0/1 bar

0 to 30 psi 0/1.6 bar

0 to 60 psi 0/2.5 bar

0 to 100 psi 0/4 bar

0 to 160 psi 0/6 bar

0 to 200 psi 0/10 bar

0 to 300 psi 0/16 bar

0 to 400 psi 0/25 bar

0 to 600 psi 0/40 bar

0 to 1000 psi 0/60 bar

0 to 1500 psi 0/100 bar

Note: Dual scale ranges (e.g. psi/bar or bar/psi) are available, as well as other units of measurement (Pa, kPa, MPa, kg/cm2 etc.)

Gauge Filling

Vibration will cause a pressure gauge to wear rapidly. Furthermore, it will cause the pointer to oscillate making reading of pointer difficult.

Filling the gauge with Glycerine, reduces vibration, thereby extending the life of the gauge and making reading easier.

Other fill fluids include Silicone Oil and Openol (for use with electrical contacts).

Gauge Lens / Window

The gauges lens, or window, can be supplied in the following materials:

- Glass (sometimes referred to as instrument glass)

- Safety Glass

- Polycarbonate

- Acrylic

Gauge Accuracy

Pressure gauge accuracy is the difference (error) between the true value and the indicated reading expressed on the pressure gauge, as a percentage of full scale span.

Usual Accuracy Classes

40mm 1.6 or 2.5%

50mm 1.6 or 2.5%

63mm 1.6%

100mm 1%

160mm 1%

250mm 1%

The accuracy class of a gauge is shown on Dial as Acc, Class, Cl or Kl (e.g. Cl 1.0 for 1% of full scale value).

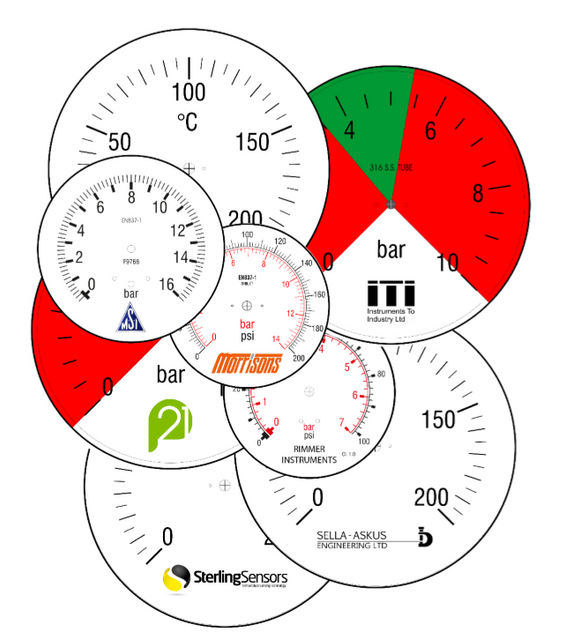

Dial Design

ITIUK can design dials to your specific requirements, including coloured segments or the addition of you/your customer’s company logo or name.